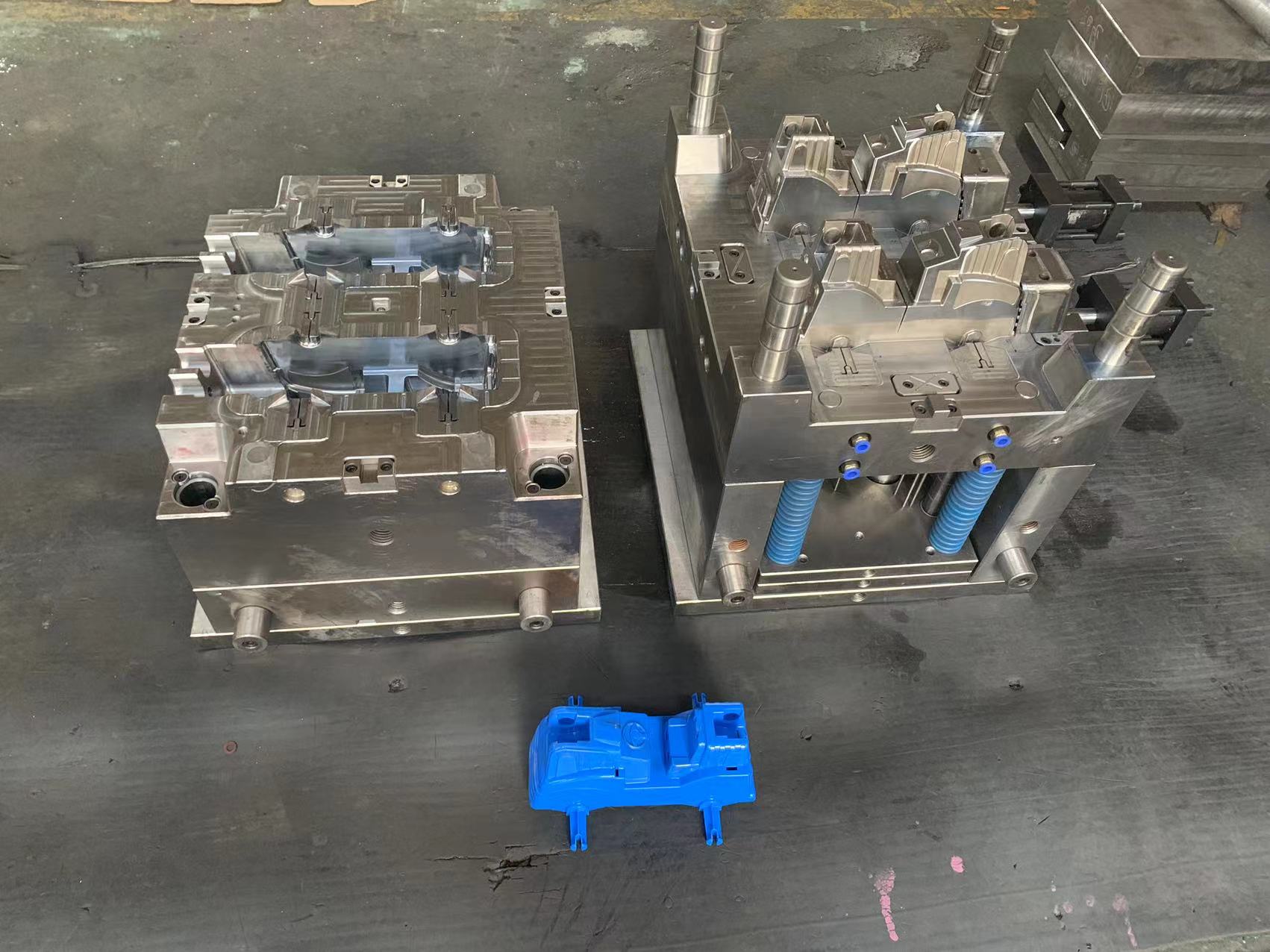

Dustbin Mould in China Taizhou manufacturer

Remo was good at making various range of dustbin, trash bin, waste bin and garbage bin moulds.

With more than 10 years experience of design and mold making for indoor and outdoor dustbins.

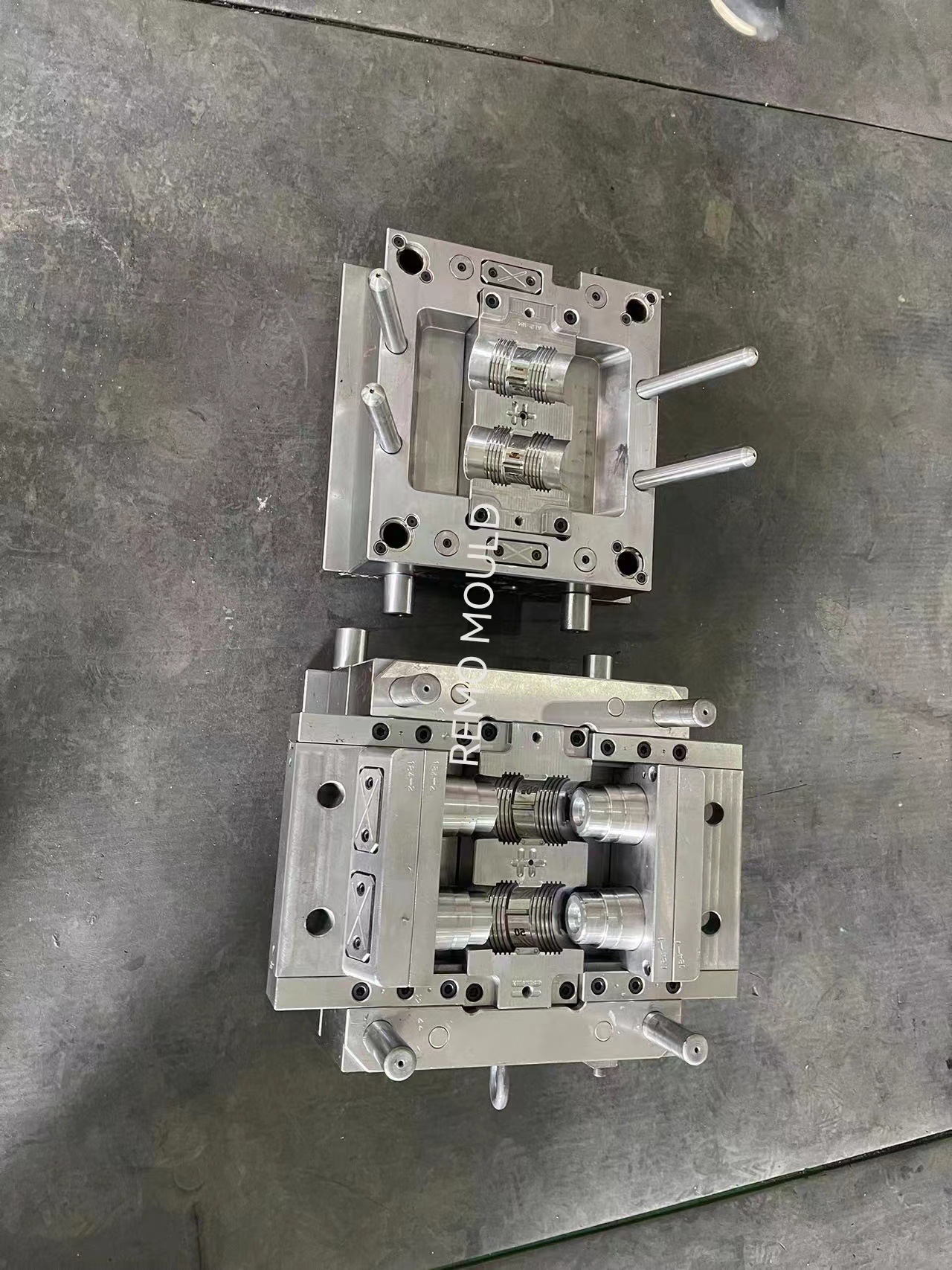

with high efficiency cooling system will shorten the injection cycle time, as a result to save more machining cost and time.

Remo concerns a lot on mold cooling system and production stability.

Our aim is to make customer run molds as fast as possible for mass production without any mold repair works.

Remo Mould is plastic dustbin mould supplier and good at making various dustbin moulds.

We can design and make plastic home dustbin mould mold,park dustbin mould,hosipital dustbin mould and especially the industries dustbin mould.

Chair Mould Making Process

Mold description: | High quality plastic dustbin mould |

Purchase order | Customer offer PO to confirm the order |

Invoice: | We send PI for payment |

Payment: | Within 3days 50%down payment by TT |

Parts design | 3days to modify and confirm |

Mold flow | Before mold design moldflow to analysis injection |

Mold design: | 5days to make mold design |

Confirmation: | 3D mold design confirmation to start machining |

Order steel: | 5days steel will arrive us for machining |

Rough machining | Raw steel flying knife processing to machine |

Heat treatment | After rough machining |

Hardness: | 48-54HRC |

Lifters: | Nitride with surface hardness 48HRC |

Fine machine: | High speed CNC, three or five axis CNC |

Fine machining | High speed engraving machining |

Fine machine: | Fine EDM, wire cutting |

Assembly: | 3days to assembly for test |

Polish: | Manual high quality process |

Surface finish: | Mirror polishing to get good appearance |

Other: | EDM or wire cutting texture |

Ejection: | Hardness HRC55-60, run automatic |

Suitable for: | Injection machine |

Test: | 50day after confirmation mould design |

Balance: | 50% balance by TT |

Delivery | 1-2weeks after balance and samples confirmation |

Transport | By sea from Ningbo Port China |